The challenge of using wood biomass for energy

Wood is one of the most important renewable energy sources—but its direct use poses challenges. Loose wood residues such as sawdust, wood chips, or shavings have low energy density, are difficult to transport, store unevenly, and lead to fluctuating combustion quality. Different moisture contents, variable grain sizes, and impurities also make it difficult to use wood biomass stably and efficiently in combined heat and power plants, industrial facilities, or pellet heating systems. For operators, this means higher logistics costs, lower efficiency, and rising operating costs.

Typical difficulties:

- Low bulk density and high storage and transport costs

- Fluctuating quality and moisture content of wood biomass

- Irregular combustion and inefficient energy yield

- Dust formation and material losses

- Limited scalability for different plant sizes

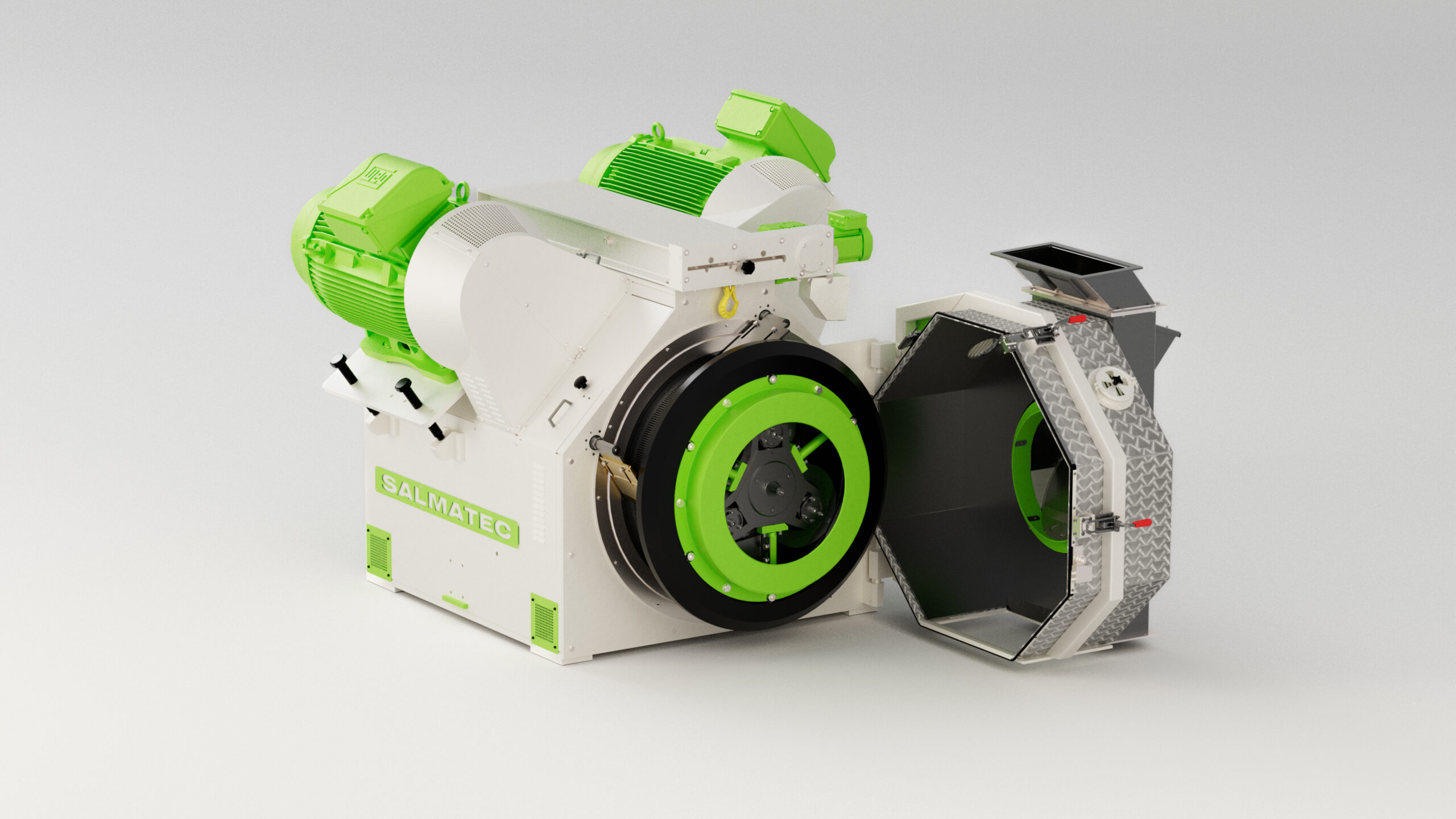

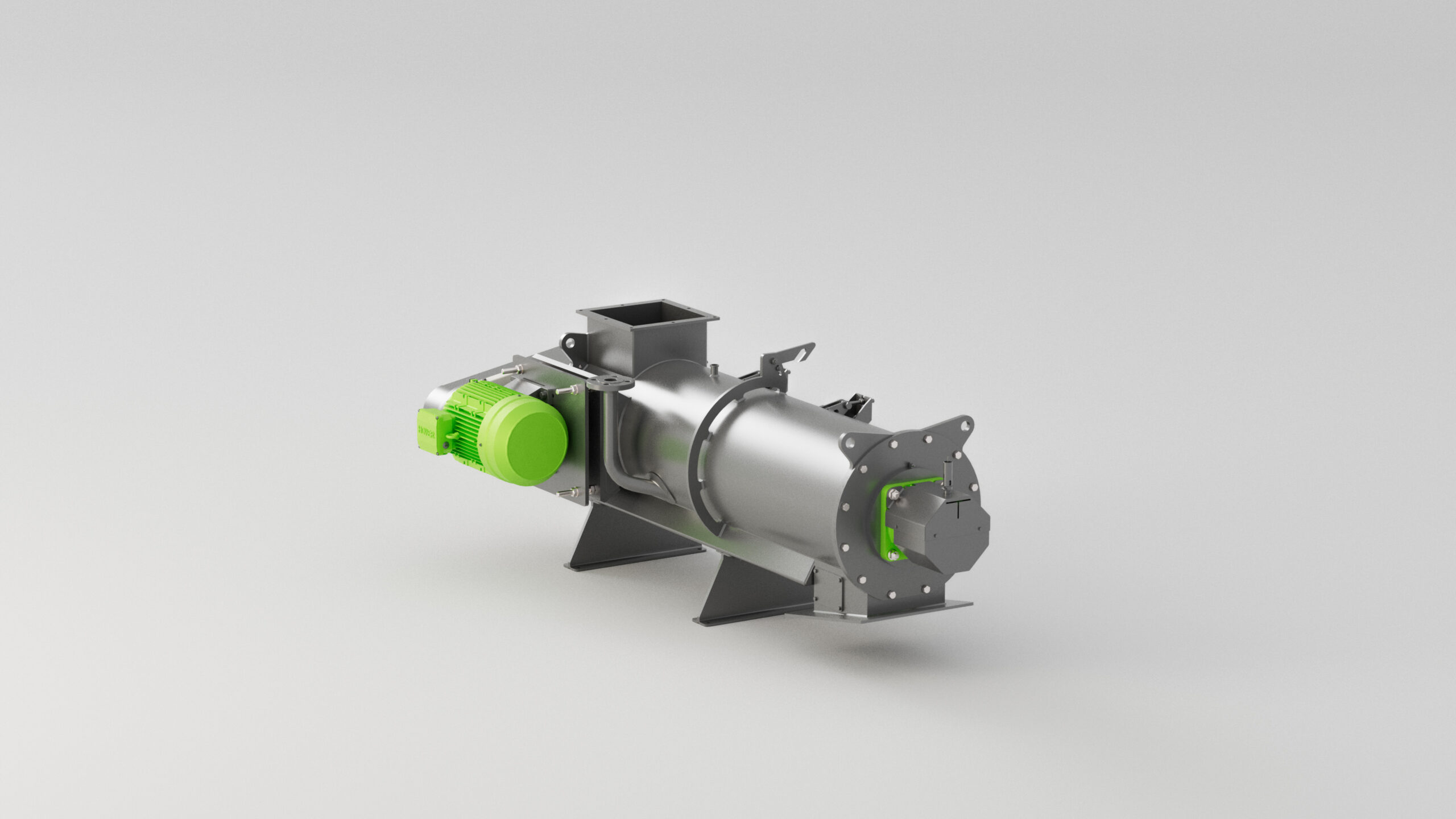

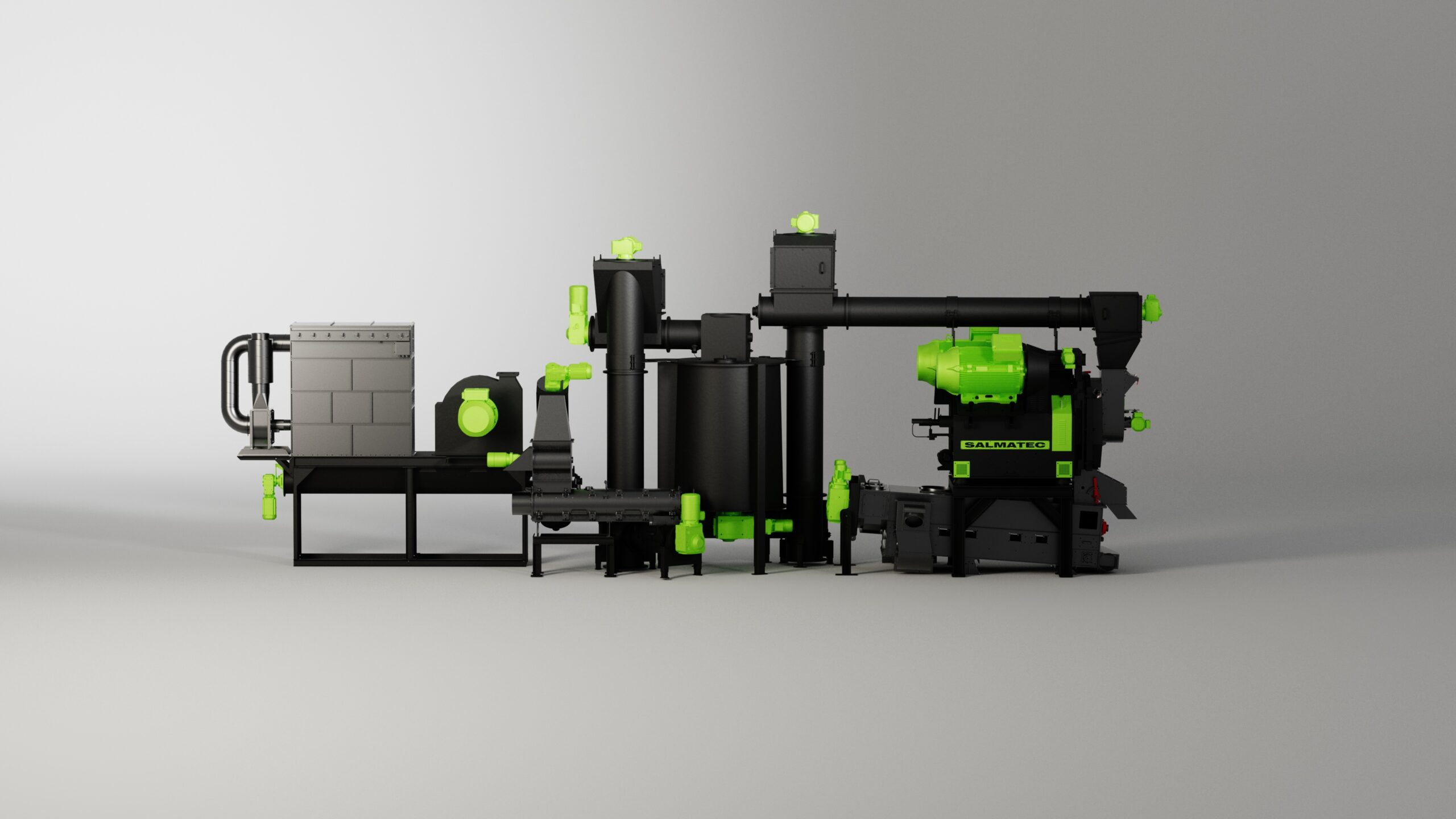

Our solution

By pelletizing wood biomass, we create an efficient, sustainable, and economical solution for energy use. Using state-of-the-art pelletizing technology, sawdust, wood chips, shavings, and other wood residues are processed into dimensionally stable wood pellets with high energy density. The result is a homogeneous fuel that is easy to store, transport, and dose precisely. The consistent quality ensures clean combustion, high efficiency, and a reliable energy supply – both for small heating systems and large industrial plants.

The advantages at a glance:

- High energy density thanks to compressed biomass

- Consistent pellet quality for efficient combustion

- Reduced transport and storage costs

- Low-dust, dimensionally stable wood pellets

- Sustainable use of residues from wood processing

References

If you have any questions about our areas of application, our experts are available to assist you personally.Please contact us by phone or email – we will be happy to help you.

We look forward to hearing from you.