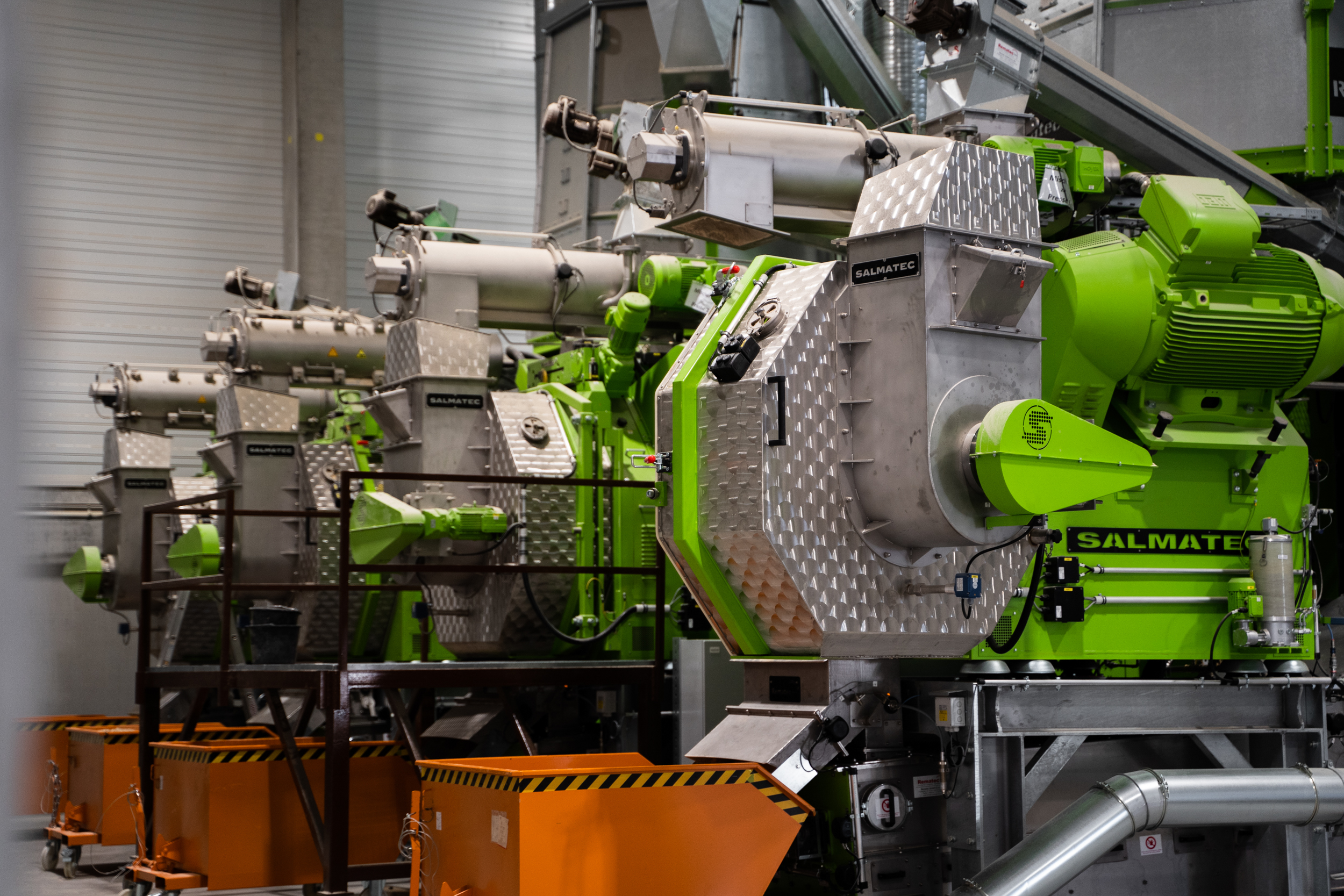

High-Performance Pellet Mills for Industrial Applications

The Salmatec Maxima series pelletizers stand for maximum efficiency, operational reliability, and long service life in industrial pellet production. Thanks to their modular machine design, the pellet mills can be precisely adapted to a wide range of raw materials, throughput requirements, and applications – from animal feed and biomass to plastics and other pelletizable materials.

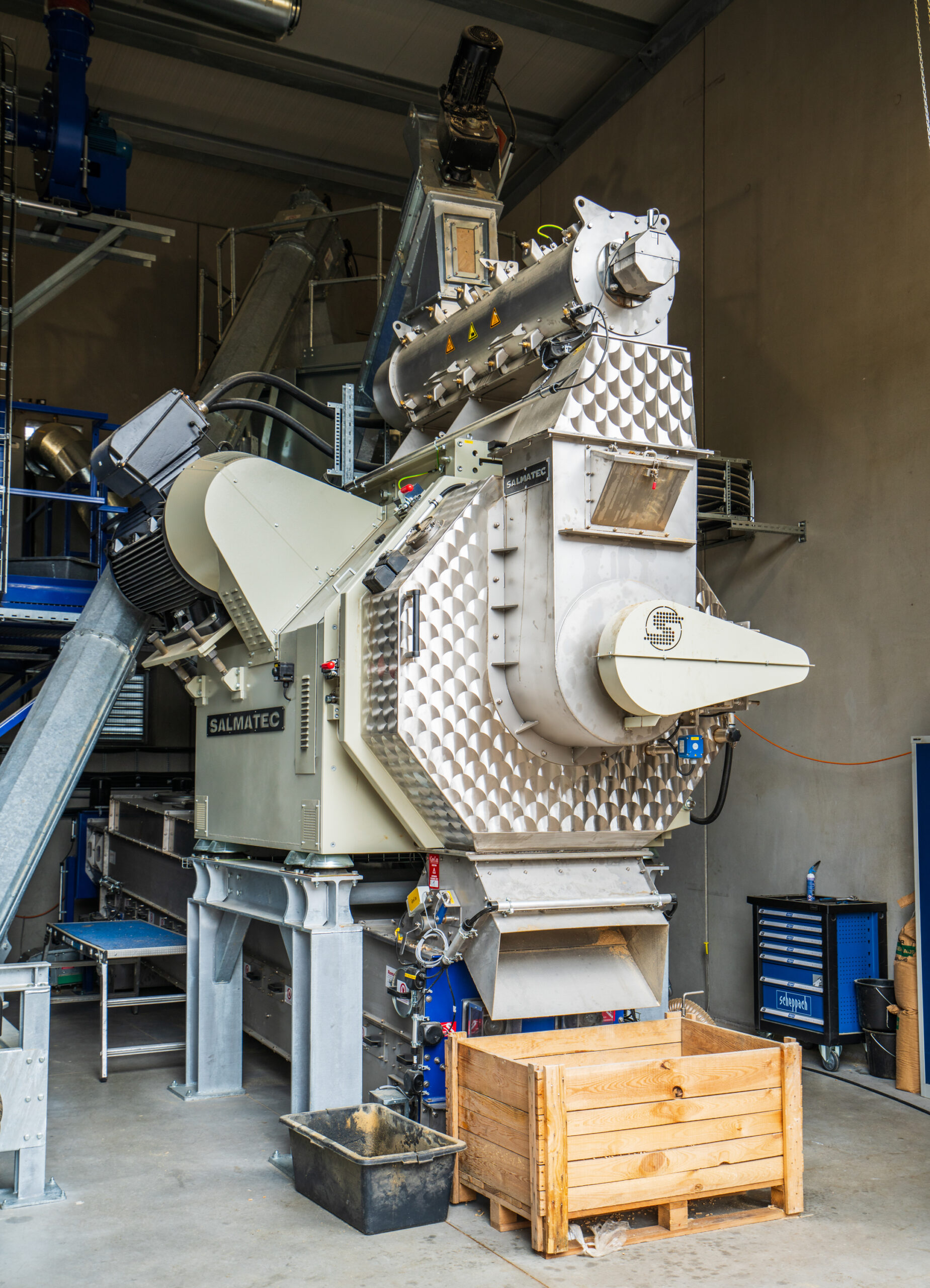

Precision Pelleting with a Vertical Ring Die

All Maxima pellet mills are equipped with a vertically operating ring die. Depending on the product characteristics and process requirements, two or three press rollers are used to ensure uniform, high pressing forces and consistently high pellet quality.

The low-noise, single-stage V-belt drive system guarantees energy-efficient and smooth power transmission. This not only reduces energy consumption and wear, but also significantly extends the service life of the entire pellet mill.

Economical, Robust, and Reliable for Continuous Operation

Pelletizers are exposed to extreme mechanical, thermal, and material-related stresses during continuous operation. This is exactly where Salmatec excels: Every Maxima pellet mill is manufactured exclusively from high-quality materials and assembled according to the highest quality standards. All machines fully comply with current safety regulations and international standards.

Intelligent Design

The core component of the Salmatec pellet mill is the generously dimensioned spherical roller bearing system of the rotor. It provides ample load capacity even under full operation and ensures smooth, long-lasting performance – even when processing demanding raw materials.

The wide-opening press door offers optimal access to the entire press chamber. This significantly reduces maintenance and tooling change times, resulting in higher plant availability and improved operational efficiency.

Individual Configuration

- Central Lubrication System

- 2 or 3 Rollers

- Hyraulic and Electric Lifting Frame

- Automatic Roller Gap Adjustment

- Overload Clutch

- Heated Access Door

- Automatic V-Belt Adjustment

- Isolated Access Door

- Maintenance Drive

- Temperature Monitoring

- Automatic Pellet Knife Adjustment

- Roller Cooling

- Individual Paint Finish

- Multi Knife

- Vibration Detection in 3 Axes

- Roller Rotation Speed Measurement

- Sampler

- Forced Feeder

- Magnetic Plates in the Inlet

- Housing Ventilation

- Material Jam Indicator

Areas of Applications

for our Pelletizers

From animal feed to waste recycling – discover how our machines process a wide range of materials efficiently and sustainably. Learn about our areas of application. Pelletizers Maxima

Pelletizers – used worldwide

References

If you have any questions about our products, our experts are available to assist you personally.Contact us by phone or email – we will be happy to help you.

Made in Germany Our products are manufactured using state-of-the-art technology, maximum precision, and many years of expertise – made in Germany