Space-Saving Complete Solution for Premium Wood Pellets

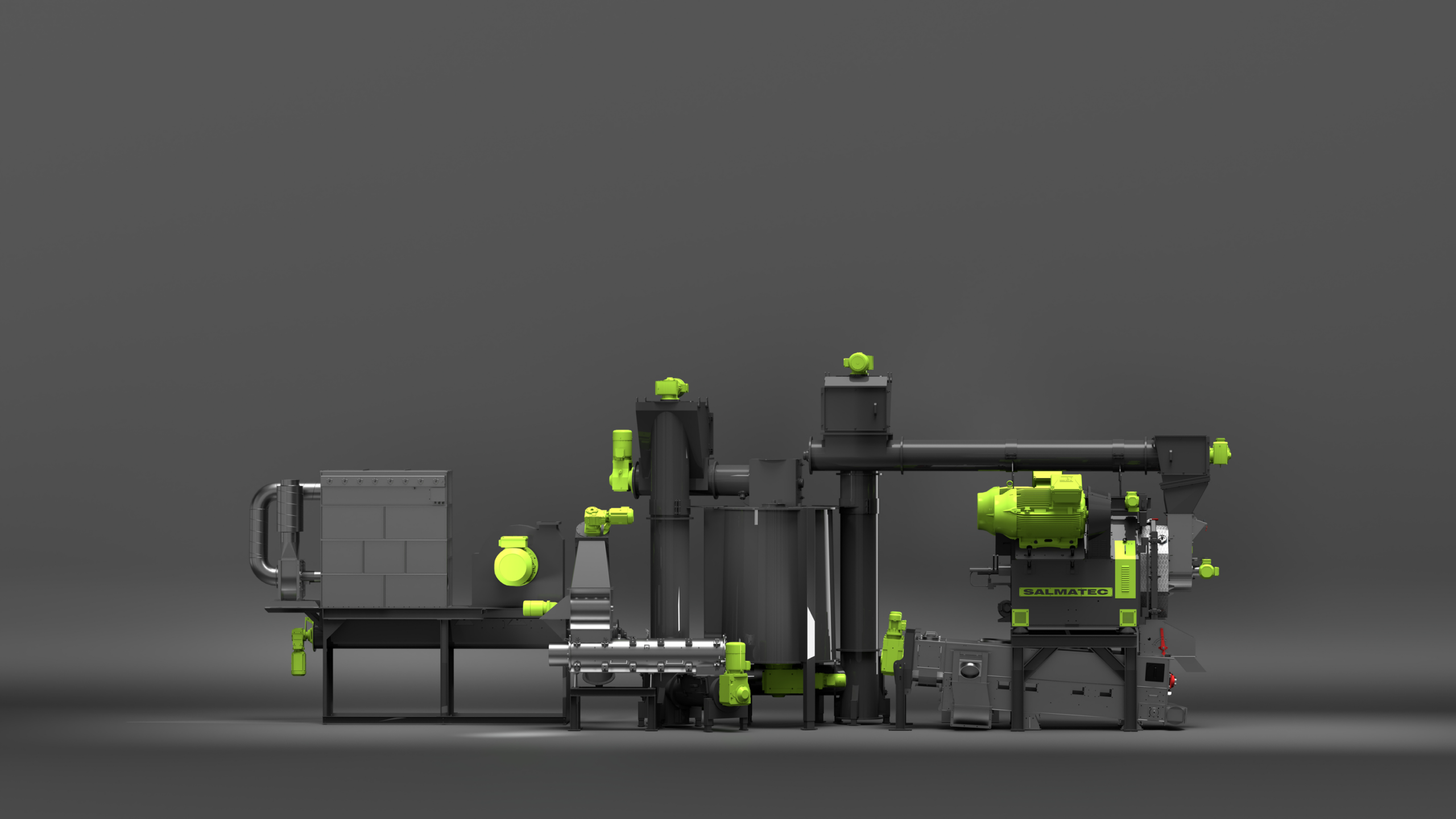

The Salmatec Compact Pelletizing Unit is an intelligent, space-saving modular solution for the production of premium wood pellets from both softwood and hardwood. The systems are specifically designed for indoor installation and combine all essential pellet production process steps into a perfectly coordinated overall concept.

Thanks to pre-assembled delivery, the compact plants can be installed and commissioned on site within a very short time. This represents a decisive advantage for operators who want to enter pellet production quickly and economically or efficiently utilize their wood by-products.

Who is The Compact Pelletizing Unit Designed for?

The Compact Pelletizing Units are designed for frost-protected indoor installation and are ideally suited for:

- Sawmills and planing mills

- Wood processing companies with by-products

- Operations with their own residual wood streams

- Waste wood processing facilities

All systems feature a maintenance-friendly design, excellent accessibility, and meet the highest standards in quality, safety, and ease of operation.

Perfectly Coordinated Processes or Consistent Pellet Quality

All components of the Salmatec Compact Pelletizing Unit are precisely matched. Conveying capacities, retention times, and the controlled addition of water and optional starch can be adjusted with high precision and controlled reproducibly. This ensures consistently high pellet quality and stable plant operation.

A Siemens S7 control system with visualization and remote access enables fully automated, low-manpower, and reliable continuous operation. For maximum operational safety, the system is equipped as standard with an integrated spark detection and extinguishing system.

Technology & Innovation – Efficient and Material-Friendly

The robust design of the Salmatec Compact Pelletizing System is engineered for a long service life in industrial operation. A key technical highlight is the innovative screen cooler, which combines multiple process steps directly downstream of the pelletizer.

In a single unit, screening, cooling, and dedusting are performed simultaneously. The freshly pressed pellets are handled particularly gently and brought to the optimal temperature and final moisture content. The result: high-quality premium pellets, achieved with low energy consumption and high material throughput.

Versatile

- Saw Dust

- Wood Shavings

- Wood Chips

- Wood Waste from the Processing Industry

- Waste Wood of Classes A1 and A2

- Mixtures of Hardwood and Softwood

Maxima Pelletizer – Sizes

Our Compact Pelletizing Unit

References

If you have any questions about our products, our experts are available to assist you personally.Contact us by phone or email – we will be happy to help you.

Made in Germany Our products are manufactured using state-of-the-art technology, maximum precision, and many years of expertise – made in Germany