The challenge of plastic recycling

Plastic waste is a growing challenge worldwide – mixed, contaminated, or unsorted plastics in particular can only be recycled mechanically to a limited extent. In practice, this results in fractions with highly variable compositions, low bulk densities, and uneven calorific values. Loose plastic residues, films, or flakes are difficult to store, costly to transport, and problematic to dose. For cement plants, power plants, and industrial consumers, this means unstable processes, fluctuating energy yields, and increased operating costs.

Typical difficulties:

- Low bulk density and high logistical costs

- Fluctuating composition and calorific values

- Poor dosing of loose plastic fractions

- Dust, fiber formation, and material losses

- High demands on process stability and plant availability

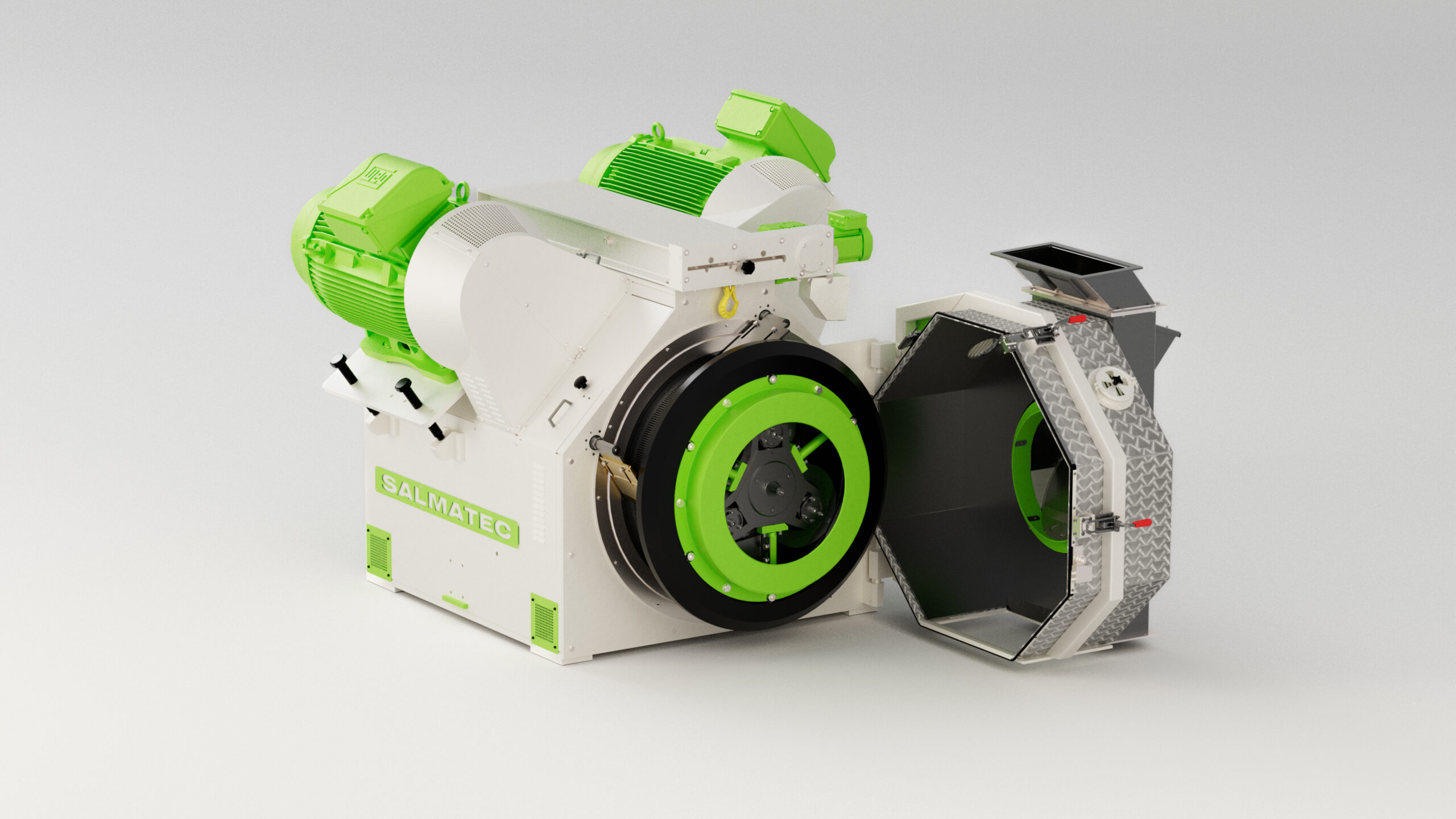

Our solution: RDF and RPF pellets

Pelletizing plastic waste produces high-quality RDF (refuse-derived fuel) and RPF (refuse plastic fuel) pellets with a defined shape, density, and energy content. Different plastic fractions are compressed into a homogeneous substitute fuel that can be stored safely, transported efficiently, and dosed precisely. The consistent pellet quality enables stable combustion and reliable substitution of fossil fuels. Our robust pelletizing technology is specially designed for abrasive, inhomogeneous materials and is suitable for both medium-sized recycling plants and large-scale industrial projects.

The advantages at a glance:

- Significantly increased bulk density and optimized logistics

- Homogeneous calorific value for stable combustion processes

- Improved dosing in industrial plants

- Reduced dust and material losses

- Efficient use of plastic waste as a substitute fuel

References

If you have any questions about our areas of application, our experts are available to assist you personally.Please contact us by phone or email – we will be happy to help you.

We look forward to hearing from you.