Competitive advantages offered by heat treated compound feed

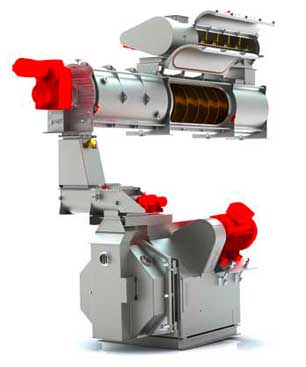

The SALMATHERM screws for heat treatment of the compound feed create competitive advantages and reduce operating costs at the same time.

SALMATHERM enable compound feed pellets to be produced with increased steam temperatures and with a long retention time.

The pelleting pressed material becomes smoother as a result of the extensive and homogeneous steam admixing process and is easier for the downstream pelleting presses to process and at the same time provides improved pellet quality.

The feed is heat treated in the SALMATHERM for two to four minutes by controlled retention. This process kills the spoilage microorganisms.

Like all SALMATEC products, it goes without saying that the SALMATHERM also conform to the latest safety requirements and guidelines.

Very high efficiency

The extremely well insulated outer sheath of the SALMATHERM and the worm shaft are actively heated with steam. This ensures that the required retention temperatures are reached and prevents the pressing material from getting attached. If required, the outer sheath can also be electrically heated.

The design of the SALMATHERM outer sheath is made entirely out of laser-welded sandwich thermal panels. This results in very short heating times and at the same time in the introduced power having a high level of efficiency.

Large cleaning ports across the entire length allow for good access to the process area.

SALMATHERM

| Model | Output of screws in tonnes per hour* | Internal diameter in mm | Inside length in mm | |

| Salmatherm SD650-4500 | 8,0 | 650 | 4.500 | |

| Salmatherm SD770-3000 | 6,0 | 770 | 3.000 | |

| Salmatherm SD830-3100 | 7,0 | 830 | 3.100 | |

| Salmatherm SD830-4000 | 10 | 830 | 4.000 | |

| Salmatherm SD830-4300 | 12 | 830 | 4.300 | |

| Salmatherm SD830-5000 | 15 | 830 | 5.000 | |

| Salmatherm SD830-6000 | 18 | 830 | 6.000 | |

| Salmatherm SD830-6500 | 20 | 830 | 6.500 | |

| Salmatherm SD920-6500 | 30 | 920 | 6.500 | |

| Salmatherm SD1100-6500 | 40 | 920 | 6.500 | |

| * based on a retention time of 2-4 minutes | ||||

Non standard adjustment is possible of course.

Process advantage

Documented quality assurance through heating, retention and pelleting.

It is possible to add a large amount of steam as the retention time can be increased considerably.

Increase in throughput, higher pellet quality with lower energy and wear part costs

Options (selection)

- Electric trough heating

- Trough heating with steam

- Shaft heating

- Product-adapted shaft speed

- Paintwork in your favourite colour

Special features

By using our laser-welded sandwich thermo panel, no periodic monitoring by the TÜV is required.

The modular design saves investment costs and makes integration into the existing systems easy.